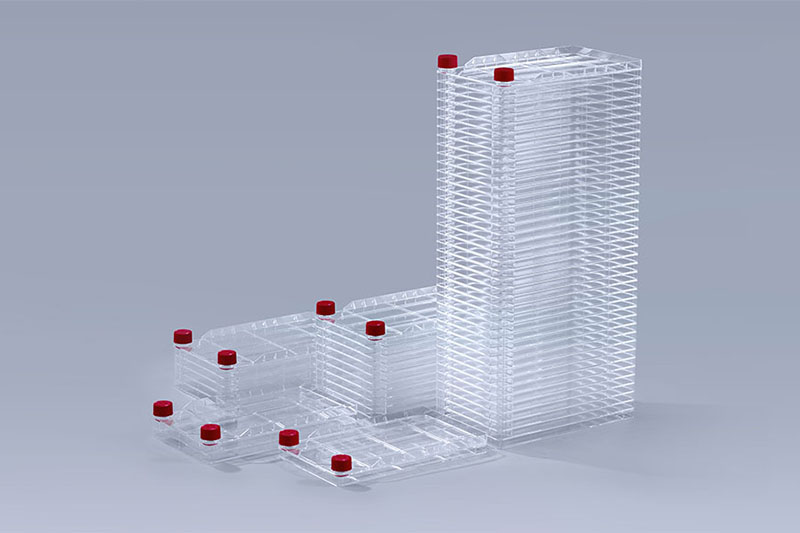

In the dynamic landscape of pharmaceutical and vaccine production, the integration of cell factory has revolutionized the industry, offering a spectrum of advantages that streamline processes and elevate productivity.

Enhanced Production Efficiency: Cell factory, leveraging living cells as mini production units, amplify efficiency. These bioreactors enable the continuous generation of therapeutic proteins, vaccines, and various biopharmaceuticals at scale, optimizing manufacturing output.

Cost-Effectiveness: The controlled environment of cell factories allows for cost-effective large-scale production. Through optimized nutrient utilization and reduced waste, these facilities mitigate unnecessary expenses while ensuring maximal output.

Quality and Consistency: Cell factory ensure product uniformity and consistency, critical in pharmaceutical and vaccine manufacturing. The controlled conditions within these factories lead to highly reproducible results, minimizing batch-to-batch variations.

Flexibility and Innovation: Adaptability is a hallmark of cell factories. Their versatility in producing a wide array of therapeutic proteins and vaccines caters to the ever-evolving demands of the pharmaceutical industry. This flexibility encourages innovation in addressing new health challenges and emerging pathogens.

Scalability: Cell factories seamlessly accommodate scaling, meeting the demands for increased production without compromising the quality or efficiency of the output. This scalability aligns with market fluctuations and growing demands in pharmaceutical and vaccine manufacturing.

Biological Safety and Regulatory Compliance: These facilities adhere to stringent regulatory standards, ensuring the safety and purity of the produced pharmaceuticals and vaccines. The controlled, sterile environment minimizes contamination risks, adhering to the highest industry standards.

In conclusion, the integration of cell factories in pharmaceutical and vaccine manufacturing stands as a transformative leap forward. Their benefits in terms of efficiency, cost-effectiveness, quality, flexibility, scalability, and regulatory compliance mark them as indispensable assets, driving the industry towards greater efficacy and innovation. As these advantages continue to unfold, cell factories remain the cornerstone of success in modern pharmaceutical and vaccine production.

The FAI climbed 5.9 percent year-on-year in the first 11 months of 2018, quickening from the 5.7-percent growth in Jan-Oct, the National Bureau of Statistics (NBS) said Friday in an online statement.

The key indicator of investment, dubbed a major growth driver, hit the bottom in August and has since started to rebound steadily.

In the face of emerging economic challenges home and abroad, China has stepped up efforts to stabilize investment, in particular rolling out measures to motivate private investors and channel funds into infrastructure.

Friday's data showed private investment, accounting for more than 60 percent of the total FAI, expanded by a brisk 8.7 percent.

NBS spokesperson Mao Shengyong said funds into weak economic links registered rapid increases as investment in environmental protection and agriculture jumped 42 percent and 12.5 percent respectively, much faster than the average.

In breakdown, investment in high-tech and equipment manufacturing remained vigorous with 16.1-percent and 11.6-percent increases respectively in the first 11 months. Infrastructure investment gained 3.7 percent, staying flat. Investment in property development rose 9.7 percent, also unchanged.

English

English

Cell Factory

Cell Factory