In today's challenging and opportunity-rich technological landscape, cell factories are gradually transforming the biopharmaceutical landscape with their revolutionary potential. This advanced cell culture method not only showcases unparalleled advantages in vaccine production but also demonstrates broad application prospects in fields such as cell therapy and monoclonal antibody preparation.

Revolutionizing Vaccine Production

As an efficient and controllable cell culture technology, cell factories have a revolutionary impact on vaccine manufacturing. Taking the hepatitis A vaccine as an example, virus amplification and cell culture can be conducted in a more convenient and safe environment, significantly improving production efficiency and the stability of vaccine quality. Furthermore, for vaccines like varicella and measles-mumps-rubella (MMR) that involve adherent cell cultures, cell factories are gradually replacing traditional processes, showcasing higher application potential and market competitiveness.

A New Hope in Biotechnology

Beyond its significant applications in the vaccine sector, cell factories hold tremendous promise in biotechnology. In key steps for producing vaccines like Japanese encephalitis and rabies, cell factories infuse new vitality into production processes through their ability to rapidly and extensively amplify cells. This technology not only significantly reduces production costs but also enhances product stability and process controllability, making it an indispensable component in the biopharmaceutical field.

International Trends and Market Applications

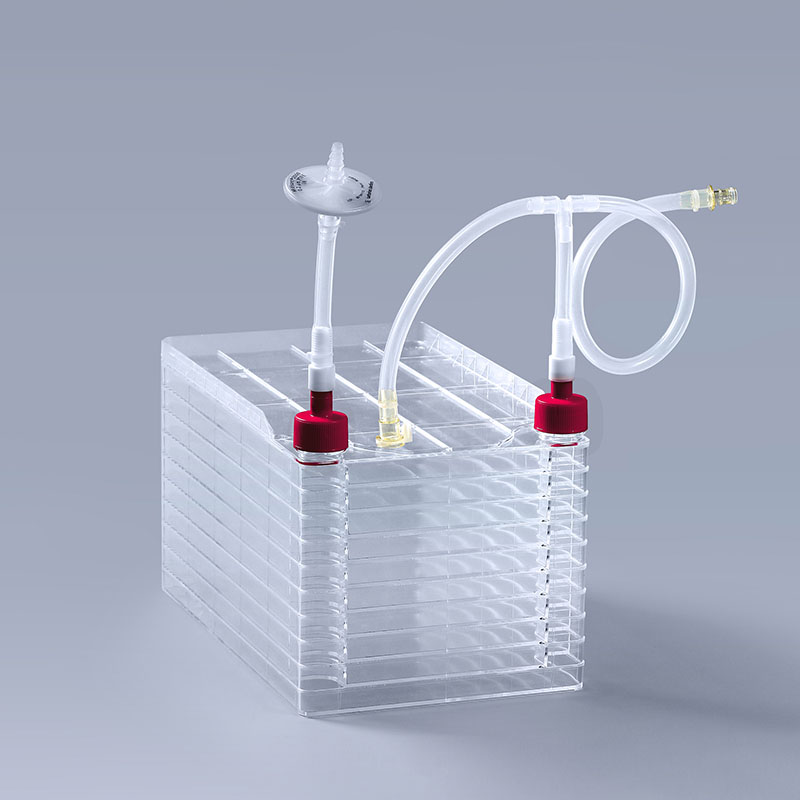

On the international market, cell factory technology has matured and is widely applied in large-scale in vitro cell culture. Whether it’s V79-4, chicken embryonic fibroblasts, or HEL299 cell cultures, these technologies have proven their advantages in production efficiency and quality control. Their user-friendly operation, compact footprint, and strong controllability provide benefits that traditional roller bottle methods lack, while also avoiding some of the application limitations faced by bioreactors, thus facilitating market promotion and application.

With the continuous advancement of technology and the increasing maturity of these techniques, cell factories are poised to become the new favorites in the biopharmaceutical field in the coming years. Their innovative applications will not only elevate the efficiency and quality of vaccine production to new heights but also open up broader prospects for the development of biotechnology.

The FAI climbed 5.9 percent year-on-year in the first 11 months of 2018, quickening from the 5.7-percent growth in Jan-Oct, the National Bureau of Statistics (NBS) said Friday in an online statement.

The key indicator of investment, dubbed a major growth driver, hit the bottom in August and has since started to rebound steadily.

In the face of emerging economic challenges home and abroad, China has stepped up efforts to stabilize investment, in particular rolling out measures to motivate private investors and channel funds into infrastructure.

Friday's data showed private investment, accounting for more than 60 percent of the total FAI, expanded by a brisk 8.7 percent.

NBS spokesperson Mao Shengyong said funds into weak economic links registered rapid increases as investment in environmental protection and agriculture jumped 42 percent and 12.5 percent respectively, much faster than the average.

In breakdown, investment in high-tech and equipment manufacturing remained vigorous with 16.1-percent and 11.6-percent increases respectively in the first 11 months. Infrastructure investment gained 3.7 percent, staying flat. Investment in property development rose 9.7 percent, also unchanged.

English

English